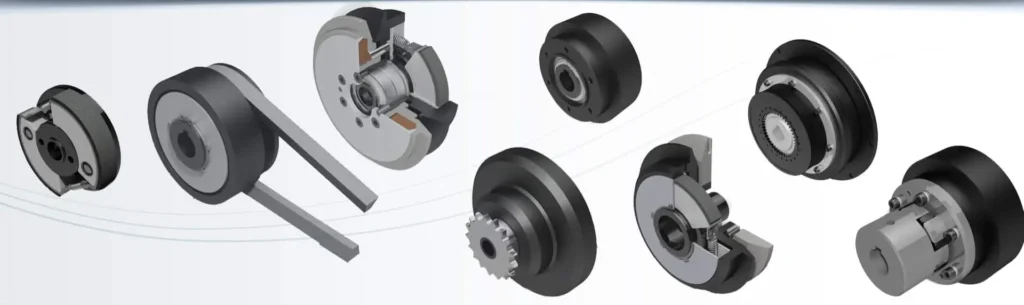

Amsbeck Maschinentechnik: The centrifugal force specialist for clutches and brakes

Customer-specific complete solutions - especially for high-quality centrifugal clutches and centrifugal brakes. That is Amsbeck Maschinentechnik.

For almost 40 years, around 35 employees in Everswinkel have been developing, producing and selling sophisticated solutions for drive technology. Amsbeck Maschinentechnik currently delivers between 80,000 and 100,000 clutches and brakes per year.

The majority of customers come from the construction machinery industry. The specialists from the heart of the Münsterland region are also trusted in the areas of transport cooling systems, pump systems, blowers, compressors and forestry machines.

Last but not least, centrifugal clutches provide the drive in karting. Anyone who has ever pressed the accelerator pedal of a kart while stationary knows how the centrifugal clutch engages the engine at the so-called switch-on speed. Without having to switch gears themselves. Ideal for drives that require a high starting torque. Similarly, the centrifugal brake does not brake to a standstill. Rather, it simply keeps the rotational speed constant. This is exactly what abseiling devices, cranes, elevators or safety gates need.

Over the years, Amsbeck Maschinentechnik has added other products such as slip-on and flange-mounted gears and hydraulically switchable clutches to its portfolio. The company is currently investing in research and development for electromagnetically and hydraulically switchable clutches.

Centrifugal force technology from the kit

Ralf Winter, head of design at Amsbeck Maschinentechnik: "In principle, we offer centrifugal clutches and centrifugal brakes from a modular system. Around 24,000 documents, almost exclusively CAD data, have been created over the years. Of course, in addition to clutches and brakes with standard parameters, we also fulfill unusual customer requests. For example, pulleys with special diameters or special connection dimensions, but also inch dimensions are on the agenda at Amsbeck. In the technical office, four designers work with Autodesk Inventor and some still with AutoCAD."

Ralf Winter continues: "Designs with AutoCAD are becoming less and less common. You are simply faster in Inventor when changes are required. I change a component and the assembly changes automatically. The same goes for the drawing derivations."

The PSP replacement favorite in advance: GAIN Collaboration

Autodesk discontinued support for the PDM solution Productstream Professional (PSP) in October 2017.

Until recently, Amsbeck Maschinentechnik also relied on the PDM system, which was popular for its high performance. Ralf Winter: "We worked with Productstream Professional for eight years. After Autodesk stopped supporting PSP, GAIN Collaboration was one of our favorites pretty early on. It is very similar to PSP. And it also impresses with its flexibility and ease of use.

To be on the safe side, we also looked at Autodesk Vault Professional, along with other competitors. However, it seemed to us to have too many formalities. Overall, it was simply too complex to use. One factor in our decision was the significantly cheaper offer compared to Vault Professional. In this respect, it is the price-performance ratio of GAIN Collaboration that ultimately convinced us quite clearly."

PDM Introduction: Test Phase and Migration

The PDM introduction and go-live at Amsbeck Maschinentechnik went smoothly.

Winter: "Everything was really perfect. After the test phase was passed, the migration of all data by GAIN Software followed very quickly. Of course, this included the transfer of all previous classes with their characteristics."

According to PSP: Classifications as desired

The designers are delighted with the new classification options available to them with GAIN Collaboration.

Ralf Winter: "With Productstream Professional, which only provided 5 classes for classification, we always had to invest more work than would have been necessary with an additional classification feature. With GAIN Collaboration, we have now expanded to 6, 7, 8 features.

Although we currently still have to update some details in the database because they were not there, we can now filter according to these features. We have now created a separate class for almost all of our components and have been able to classify them accordingly."

And so the specialists for centrifugal clutches and brakes have well over 100 classes for clutch properties or individual parts. Winter continues: "Our clutches and brakes are mainly installed in conjunction with combustion engines. The clutches are usually pushed onto shafts. This means that a profile hub always has the shaft diameter as a reference - as a classification feature. Just like the feature "groove width" or the information about which ball bearing is on this hub. Or the "flyweight used" among other features. We also have a class of coupling types for our couplings with belt or flange drive. With elastic or highly elastic coupling. And they all have their specific, different features."

Intuitive operation after a short introduction

A PDM system should be easy to learn and support its users as quickly and easily as possible.

The designers in the technical office of Amsbeck Maschinentechnik agree: "In our specific case, extensive training as one would imagine was not necessary. Much of GAIN Collaboration is self-explanatory. Of course, we received a demonstration from GAIN Software. And then we had a few questions at the end. The bottom line, however, is that the general use of GAIN Collaboration is really surprisingly simple. We had all imagined this point to be more comprehensive. After just a day and a half, we were able to work with the system without any problems. Performance has also noticeably improved. We simply carry out some display options ourselves, such as masks or extending classes. Otherwise, we mostly rely on the employees at GAIN Software. They always help us out pretty quickly."