Product data management for a distinctive company

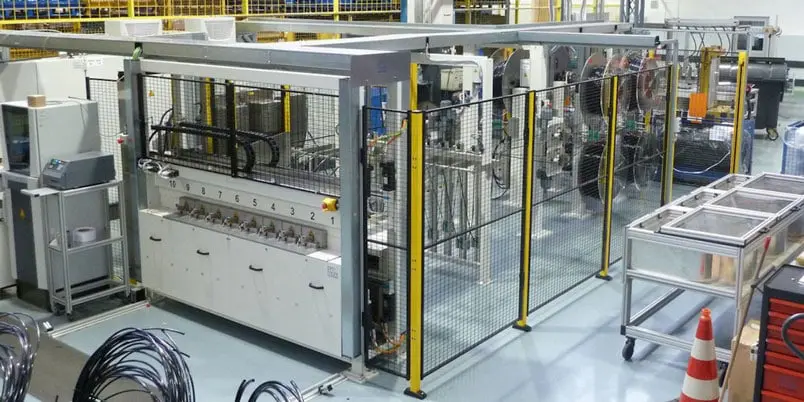

Whenever the reliable marking of metals, plastics or other materials is required, promark automation is an experienced contact. The team of experts from Eigeltingen on Lake Constance already had extensive experience in marking and printing technology before it was founded 7 years ago. Today, promark automation carries out markings using lasers, inkjet printers and other processes. The marking technology is integrated as a stand-alone solution or directly into production machines in the automotive, extrusion, medical or aerospace sectors.

Switching from Productstream Professional to the PSP successor GAIN Collaboration

Due to the impending discontinuation of Autodesk Productstream Professional (PSP), promark automation had been looking for an appropriate PSP successor for some time.

"The more similar and functional the new PDM system is to PSP, the better," recalls Patrick Störmer, designer and PDM system administrator. "We immediately noticed GAIN Collaboration with its interface that is very similar to PSP."

Störmer: "The actual PDM introduction only took three or four days. Before the changeover, we migrated all Inventor data to the Inventor version R2015 that we were using, i.e. updated it.

This was a very good control for us. On the one hand, we were able to check the quality of our data. On the other hand, it gave us the best conditions for transferring the data to the new PDM system without errors or loss.

The switch to the PSP successor took place in two steps. In the first step, the metadata from the PSP database was transferred to GAIN Collaboration. And this was done without any loss. In the second step, our actual documents, such as the Inventor data, were transferred to the GAIN Collaboration archive directory.

These migration steps were completed overnight and the next morning all data was available in GAIN Collaboration. Without exception, all data was transferred in its original quality. We are very satisfied with the result. Especially since everything was processed in such a short time," says Störmer.

PDM management of CAD, MS Office documents and neutral data

A promark automation marking machine as a stand-alone solution consists of a basic assembly with an average of 200 - 300 parts. These are made up of a frame and - depending on the application - various purchased parts in Step format. In addition, there are manufactured parts such as bent sheet metal parts or milled parts.

Currently, around 40,000 documents are stored machine-related with GAIN Collaboration - primarily Autodesk Inventor and Step formats.

"Before GAIN Collaboration, we worked with Autodesk Productstream Easy, so managing MS Office documents was not possible. Now we can gradually store MS Office data for the projects. For example, data sheets in PDF or calculations in Excel format," explains Störmer.

Current CAD Workplaces and Outlook for the Future

Two CAD workstations are currently equipped with GAIN Collaboration Professional. Patrick Störmer: "After a longer test phase, we want to equip various office workstations in sales and administration with GAIN Collaboration Office. In case you want to quickly look something up. In addition, everyone could then use the search and filing functions of GAIN Collaboration."

In order to also benefit from complete parts lists, the Eigeltingen-based company is planning to equip two existing E-Plan workstations with the appropriate interfaces. "Then we can ultimately generate a complete parts list at the push of a button. And then simply order the required electrical and mechanical parts efficiently. It's basically the all-round happy solution," smiles Störmer.

Simple processes with suppliers

So far, GAIN Collaboration has only been used internally. Suppliers are not yet given any insight into the PDM system. Until that happens, promark automation likes to use one or another of GAIN Collaboration's job server functions. For example, the automatic creation of PDF files for suppliers. Störmer: "For binding order templates, we simply let GAIN Collaboration export parts lists to MS Excel. And for repeat orders or spare parts, GAIN Collaboration lists the corresponding article numbers quickly and easily."

Highly valued: PDM handling and operation

The labeling professionals find the operation of the new PDM system to be very intuitive and clear:

Störmer: "You can find your way around GAIN Collaboration really quickly. It's almost intuitive. It took us very little time to get used to it. Files can be easily saved directly in GAIN Collaboration using drag & drop. And then there are the numerous, flexible configuration options: you can change something quickly yourself. That's really practical," says Störmer happily. "I also really appreciate the data masks, which I can easily adapt to my individual needs. For example, GAIN Collaboration only shows me the information I really need. And not to forget the search function. It's very easy to use and helps us find the right components extremely quickly."

Thanks to the administrator training, Patrick Störmer was able to quickly make some personal optimizations to his search mask.

Familiar and faster: The Inventor interface

"The PDM Inventor interface is really great," says Störmer. "And because you work locally, it's also much faster than we were used to. In the interface, we find the tools that we had in PSP. For example, for replacing components with a copy or revision. Or that we can insert and open components from GAIN Collaboration in Inventor using drag & drop during the design process. Handling frame generator parts is also simple. GAIN Collaboration automatically sets the display name for the documents in Inventor. This means that we can now finally see which parts are contained in an assembly directly in the Inventor browser using the display name and number. And creating drawings for models is now much easier. All we have to do is transfer the drawing newly created in Inventor to GAIN Collaboration, i.e. connect it. All information from the model is then transferred to the entry. Fully automatically. And if we do make a mistake here, it can be quickly corrected by GAIN support," says Störmer.

PSP successor with the best care and support

They are also very satisfied with the performance, responsiveness and reliability of GAIN support.

"It really works very well. The support always thinks ahead and usually solves problems directly over the phone. Or we get direct feedback on when we can expect a response," says Störmer with satisfaction.

GAIN Software has also implemented special requests quickly and without any red tape. For example, the automatic export of drawing sets at the touch of a button while working. Or the user interfaces, which now look exactly as you would expect from promark automation.

Transition as advancement

All in all, the switch from Productstream Professional to the new PDM system GAIN Collaboration was a real step forward for the Eigeltingen company.

Patrick Störmer: "GAIN Collaboration meets all our expectations in terms of functionality, overview and ease of use. Many things have become easier. And we will be even more productive once our other PDM plans have been implemented with GAIN Collaboration."